Explosion-proof (EP) fume hoods are engineered to reduce ignition risks in environments where the air contains high concentrations of flammable vapors or particulates. Despite their name, these hoods are frequently misunderstood. Many assume that working with flammable chemicals automatically requires an explosion-proof hood—but the real determining factor is the room classification, not just the substances in use.

In this post, we’ll clarify the most common misconceptions surrounding EP fume hoods and offer practical guidance rooted in NFPA and OSHA standards. The goal: help you make informed decisions about lab design, safety, and equipment selection.

Myth #1: “Explosion-proof hoods come fully certified.”

It’s easy to assume that an EP fume hood arrives certified and ready to go. It doesn’t.

A hood is only considered explosion-proof once it’s installed correctly in a classified hazardous room—typically rated as Class I, Division 1 or 2 per NFPA 70: National Electrical Code. What ships from the manufacturer is a modified version of a standard hood: no wiring, no switches, and an explosion-proof light fixture (minus the bulb).

Everything else—including conduit, wiring, switches, and power connections—must be installed on-site, per local code, by a licensed electrician. Certification isn’t possible at the factory level because it depends on how and where the hood is installed.

Here’s the kicker: if the room contains standard light switches or outlets, it’s not explosion-proof. Installing an EP hood in that environment may provide a false sense of safety. Worse, it can negate any protective value the hood offers.

Myth #2: “If I’m working with flammable chemicals, I need an EP hood.”

Not necessarily. This myth persists because “explosion-proof” sounds like a sensible precaution. But the truth is more nuanced.

EP hoods are required when the room’s atmosphere may contain flammable vapors at concentrations near or above the lower explosive limit (LEL). In most labs, that’s not the case.

Standard chemical fume hoods don’t have electrical components in the air path. Lights are isolated behind thick safety glass, and airflow constantly dilutes vapors—making it hard to reach dangerous concentrations. As long as the fume hood maintains vapor levels below 25% of the LEL, it falls within safe operating limits.

According to NFPA 45, the interior of a lab hood is exempt from electrical classification unless an “unusual hazard” is present. For context, here’s a practical example: evaporating 2 pints of methanol per hour at 70°F requires just over 22 CFM of exhaust to stay below the 25% LEL threshold. Most hoods easily exceed that volume.

So, unless your ventilation is inadequate or there’s a real risk of vapor accumulation due to equipment failure, a standard hood is typically sufficient—even when flammables are in use.

Myth #3: “Explosion-proof hoods protect users during an explosion.”

This one is especially dangerous. EP hoods are not designed to contain explosions—they’re meant to prevent them.

Yes, the sash provides a barrier, but it’s still glass. In the event of an internal explosion, the user may be exposed to the blast through the sash or opening. EP hoods don’t include blast-rated construction or containment features. Assuming they do creates a serious risk.

If explosion containment is the concern, you’ll need completely different equipment—and a full review of your lab’s hazard classifications.

Myth #4: “Any lab can use an EP hood without changing infrastructure.”

Think again. Installing an EP hood without upgrading the room to meet Class I standards makes the entire setup ineffective.

A true explosion-proof environment requires more than just a modified hood. You’ll need:

- An EP-rated switch (or a non-rated switch installed outside the classified area)

- Metal conduit for all wiring

- External EP-rated outlets (too large for fume hood corner posts)

- A licensed electrician to handle the installation

These upgrades increase both cost and complexity—and only make sense if your lab environment warrants a hazardous classification. Otherwise, a standard fume hood is not only more appropriate—it’s safer.

Conclusion: Know the Room Before Choosing the Hood

EP fume hoods have their place—but it’s a very specific one. They’re designed for hazardous rooms where flammable vapor concentrations are high and continuous. They’re not a catch-all solution for any lab that handles flammable chemicals.

In most cases, a well-functioning standard fume hood—with good airflow and no internal spark potential—is the right choice.

Before specifying an EP hood, ask the following:

- Does the room contain standard electrical outlets or switches?

- Can vapor concentrations exceed 25% of the LEL?

- Are all electrical components located outside the air stream?

- Does the installation plan meet NFPA 70 and OSHA 29 CFR 1910.307?

Actionable Takeaways for Lab Managers and Safety Professionals

- Assess the room, not just the chemicals—Classification matters

- Don’t confuse prevention with protection—EP hoods reduce ignition risk but don’t contain blasts

- Watch for misleading assumptions—Certification depends on installation, not manufacturing

- Consult your EH&S team before upgrading to EP systems

- Keep airflow documentation on hand to support compliance decisions

The right fume hood choice starts with understanding your lab’s real risks—not just its materials. When in doubt, trust the standards, work with qualified engineers, and resist the urge to overengineer where it’s not warranted.

Related Products

-

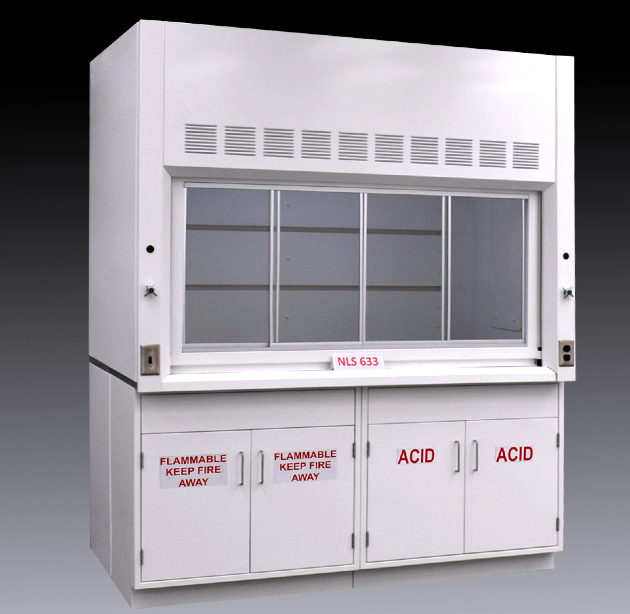

10′ Fisher American Fume Hood w/ ACID Storage Cabinets

$21,625.00 -

10′ Fisher American Fume Hood w/ Blue ACID & General Storage Cabinets

$19,925.00 -

10′ Fisher American Fume Hood w/ Blue ACID Storage Cabinets

$21,625.00 -

10′ Fisher American Fume Hood w/ Blue Flammable & ACID Storage Cabinets

$21,625.00